- Eremex

- Products

- TopoR

- Competitive Advantages

- PCB design time reduction

PCB design time reduction

TopoR allows to reduce design time up to several times

«Instant routing» of 100% of wires on a board

TopoR provides 100% routed layout almost instantly within a few seconds. All connections are routed even if technological constraints are violated. Autorouting is followed by the multiobjective optimization by calculating different variants of laying wires. During the optimization process the overall wire length is optimized as well as the number of vias and places with smaller clearance.

The routing process can be stopped at any moment, and the engineer can immediately define the technical possibility of routing the board within the limits of the specified number of layers, defined clearance size and other technical limitations based on the routing density and the amount of technical constraints violations. This helps to avoid waiting for many hours which is typical for the traditional autorouters. Engineers using the traditional systems can spend significant amount of their time trying to get the suitable results for different variants of routing strategy.

TopoR is capable of performing parallel computing, speeding up the result achievement by many times

TopoR can perform parallel optimization of several alternative topology variants, which differ in optimized parameters, while a user is offered a choice of selecting one or several variants. This feature allows for organizing the distributed routing – parallel topology optimization by using several processor cores and/or several computers within one local network. This allows to significantly reduce machine time especially for routing complex multi-layer boards.

The innovative topology router significantly increases engineers' productivity

TopoR support two types of manual topology routing of PCBs – graphical and topological. Topology router automatically calculates the optimal shape and wire positioning in terms of the defined topology. This allows engineers to concentrate on the topological aspects of design without paying attention to the wires shape and observing technological restrictions. Touching or even number or wires intersections is not considered a violation. It is sufficient to push a button and move to the topological mode to “string” the wires automatically and move them to the necessary distance.

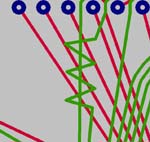

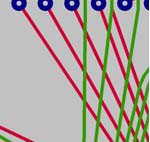

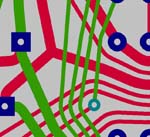

Topology fragment:

a) Touching or even number or wires intersections is not considered a violation;

a) Touching or even number or wires intersections is not considered a violation;

b) With a push of a button the wires automatically “strung” and moved to the necessary distance;

b) With a push of a button the wires automatically “strung” and moved to the necessary distance;

One of the unique features of TopoR is its capability to move components on the routed board while preserving the connections topology. Geometry and positioning of components are automatically calculated to comply with the new components position.

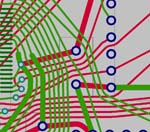

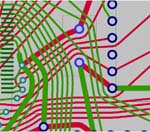

PCB fragment before and after moving a capacitor.

Movement of components, vias and wire branching is used to decrease wires length, provide the utmost clearance space which should be not less than required (to eliminate the narrow spaces). Movement can be performed both manually and automatically, and the most effective wires shape is defined immediately.

During the automatic movement of the board components, the wires branching points and vias are set to optimal positions.

During the automatic movement of the board components, the wires branching points and vias are set to optimal positions.

All this significantly simplifies and speeds up the routing process, allowing to avoid necessity of constantly observing technical limitations.

“One of our boards has been routed by a qualified engineer for 2 weeks. In order to study the capabilities of TopoR CAD system we passed this task to Eremex specialists and were impressed to learn that they have done this job within an hour. Moreover the majority of work was done by automatic routing with minor manual corrections. However the routing quality was better then the quality of our variant.” - Our Customer.

The board that was routed manually during a 2-week period. The number of vias – 510. Trace length – 6.5 m.

The board that was routed manually during a 2-week period. The number of vias – 510. Trace length – 6.5 m.

The board routed by TopoR within an hour (20 min for autorouting and 40 min for manual routing). The number of vias - 432. Trace length –5,11м.

The board routed by TopoR within an hour (20 min for autorouting and 40 min for manual routing). The number of vias - 432. Trace length –5,11м.